Aluminum alloy materials

Solutions for machining:

Carbide end mills

Ultrafine grain cemented carbide material.

These end mills, made from ultra-fine grain cemented carbide, offer an exceptionally sharp cutting edge that allows for efficient machining of lightweight aluminum alloys. The wide chip space optimizes chip evacuation, ensuring a smooth and unobstructed cutting process.

Product diameter range: ø6 ~ ø20.

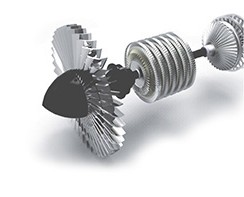

PCD Cutters

Exceptional surface finish and cutting edge:

These PCD (polycrystalline diamond) cutters offer a smooth surface and an extremely sharp cutting edge, which minimizes material adhesion.

With a tip concentricity controlled to 0.002, these tools ensure high-precision machining.

The design with ample chip space ensures excellent evacuation and dissipation of heat, reducing cutting impact and allowing for light and efficient machining.

Product diameter range: ø6 ~ ø32.

Tungsten Carbide Dagger-Type Drill Bit

Multifunctional cutting tool for T700 composite material

This multifunctional cutting tool is capable of performing drilling, reaming, and counterboring operations on T700 composite material with a single tool. It offers high processing efficiency, reduces tool costs per machine, and enhances durability.

- 3-in-1 Efficiency: Drilling, reaming, and counterboring with a single tool.

- High efficiency: Reduces cycle times and increases productivity.

- Economic: Minimizes tool costs and machine downtime.

- Exceptional durability

Range of diameters:

- General diameters: ø6 ~ ø20.

- Customizable

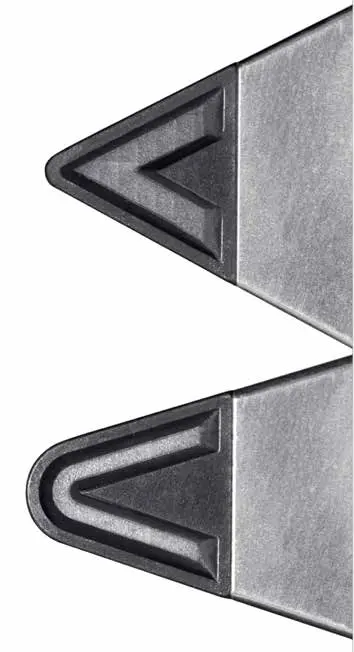

Sintered PCD spiral drill

Machining of T700 composite material with precision and durability:

This spiral drill, made with sintered PCD, is designed for machining T700 composite material. Its PCD tip structure and extremely sharp cutting edge effectively inhibit material delamination and burr formation, while significantly improving the tool's durability.

- High-quality PCD tip: Ensures a precise and clean cut in composite materials.

- Extremely sharp cutting edge: Minimizes delamination and burrs.

- Exceptional durability: Extends the tool's lifespan and reduces replacement costs.

Range of diameters:

- General diameters: ø2 ~ ø20.

- Customizable

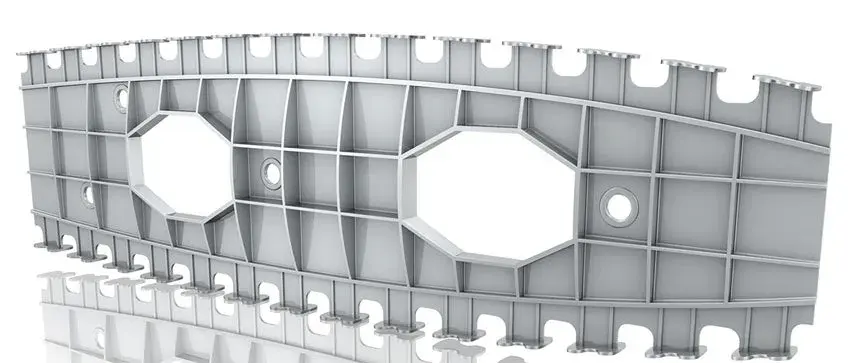

Composite tool for drilling, reaming, and countersinking

Two structures for efficient machining:

This composite tool is available in two structures: sintered PCD and PCD with inserts. Both versions are designed for machining T700 composite material, but the sintered PCD tool offers superior performance in laminated materials.

- Combined operations: It performs drilling, reaming, and countersinking in a single operation, eliminating the need to remove, change, or reposition the tool.

- Efficiency: Significantly reduces processing time.

- Precision: The polishing edge compresses the wall of the hole for a high-quality finish.

Range of diameters:

- General drill diameters: ø2 ~ ø16.

- Customizable

PCD Tapering Machine

Standard and custom countersink angles:

This countersink is available in a full range of standard countersinking angles of 90°/100°/120°/130°, in both metric and inch specifications.

- Exceptional durability: The PCD cutting edge offers a long lifespan.

- Superior surface quality: Maintains an excellent surface roughness index.

- Precision: High precision in the thread for a quick drill change.

- Wear resistance: The guide post offers wear resistance.

Range of diameters:

- Range of diameter on the guide: ø2 ~ ø16.

- Customizable

Sintered PCD Cutters

Exceptional performance for composite materials:

Our sintered PCD end mills offer high-quality spiral machining for composite materials ranging from T700 to T1000. With a sharp cutting edge that facilitates chip removal, these tools ensure exceptional processing quality and increased efficiency.

- Sharp cutting edge: Allows for smooth and efficient machining.

- Optimized chip evacuation: Reduces heat buildup and extends tool life.

- Superior processing quality: Achieves high-precision surface finishes.

- Greater efficiency: Reduces cycle times and increases productivity.

Range of diameters:

- Range of diameter on the guide: ø6 ~ ø12.

- Customizable

PCD two-flute ball end mills

Unique design for precise machining:

Our two-flute PCD spherical end mills feature a unique design with a cutting edge that crosses the center, making them ideal for machining spherical shapes, profiling, and other applications. These tools are suitable for machining T700 composite materials and aluminum alloys.

- Wide range of applications: Perfect for machining spherical shapes, profiling, and other operations.

- High efficiency: Reduces cycle times and increases productivity.

- Sharpening and coating service: Extends the tool's lifespan and optimizes the investment.

- Excellent value for money: It offers superior performance at a competitive price.

Range of diameters:

- Range of diameter on the guide: ø6 ~ ø20.

- Customizable

PCD wavy edge milling cutter

Efficient machining with a superior finish:

This wavy-edged end mill is designed for rough machining of T700 composite material. Its wavy edge structure effectively reduces cutting force, which improves machining efficiency and provides better surface finish quality.

- Ideal for roughing: Optimized for rough machining of T700 composite material.

- Reduction of cutting force: Allows for more efficient machining and reduces the load on the machine.

- Better surface finish: Produces a smoother and more uniform surface.

Range of diameters:

- Range of diameter on the guide: ø6 ~ ø20.

- Customizable

PCD end mills with 2 or 3 flutes

Efficient machining with a superior finish:

This PCD end mill with central cutting capability is ideal for machining T700 composite material. It allows for milling and finishing operations on flat surfaces with a single tool.

- Sharp PCD edge: Cuts composite material fibers with ease and precision, extending the tool's lifespan.

- High-quality surface finish: Produces smooth and even surfaces.

- Versatility: Ideal for milling and finishing on flat surfaces.

Range of diameters:

- Range of diameter on the guide: ø3 to ø20.

- Customizable

End Mill for Kevlar and Carbon Fiber

Specialized edge design for a clean cut:

This cutter, with a blade specially designed for Kevlar, cuts the fibers efficiently, preventing the formation of burrs and the delamination of the material.

- Light cutting: Reduces the load on the machine tool.

- High efficiency: Allows for fast and precise machining.

- Exceptional durability: Equivalent to that of high-quality imported tools.

- Compatibility: Works with a wide range of machine tools.

Range of diameters:

- Range of diameter on the guide: ø3 ~ ø12.

- Customizable

Diamond Coated End Mill

Specialized edge design for a clean cut:

This diamond-coated end mill is designed for roughing and finishing machining of carbon fiber reinforced polymer (CFRP) and glass fiber reinforced polymer (GFRP) materials. Its left and right spiral cutting edges effectively inhibit delamination and burr formation, making it ideal for insert milling and side milling in carbon fiber materials, such as T700.

- Light and fast machining: The diamond coating allows for more efficient cutting and reduces the load on the machine tool.

- High-quality surface finish: The machined parts are free of burrs and have a high smoothness.

- Versatility: Compatible with a wide range of machine tools.

Range of diameters:

- Range of diameter on the guide: ø3 ~ ø12.

- Customizable

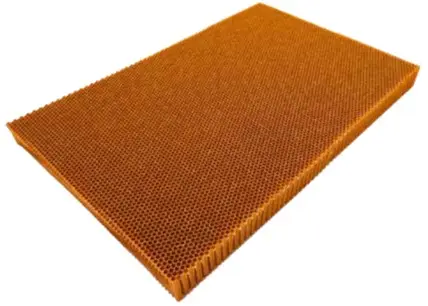

Crusher mill (split type)

Superior efficiency and surface quality:

Generally, ultra-thin paper honeycomb parts are processed with ultrasonic tools. However, the GWT crusher mill for machining Nomex® paper honeycomb offers an efficient alternative for processing this material with a high surface quality.

- High machining efficiency: Reduces cycle times and increases productivity.

- Exceptional surface quality: Produces honeycomb parts with a flat surface and no burrs, eliminating the need for an additional deburring process.

Range of diameters:

- Range of diameter on the guide: ø37 ~ ø61.5 (1.45" to 2.42")

- Customizable

Crusher mill (solid type)

Superior efficiency and surface quality:

Comprehensive design for high-performance machining:

This integral type crusher mill is designed for the efficient machining of aramid paper honeycomb. Its integral design and the cutting edge with spiral grooves allow for superior cutting speeds and feeds.

- Higher speed and feed: The integral design and spiral grooves optimize cutting performance.

- Versatility: Available in a wide range of sizes to accommodate various honeycomb core shapes.

- Efficient chip evacuation: Reduces the resistance to chip evacuation and separation, making the machining process easier.

Range of diameters:

- Range of diameter on the guide: ø22 ~ ø95 (0.88" to 3.75")

- Customizable

Straight ultrasonic cutter

Clean and precise machining without burrs:

This straight ultrasonic cutter is designed for machining aramid paper honeycomb, providing a clean and precise cut without generating dust or waste.

Higher speed and feed: The integral design and spiral grooves optimize cutting performance.

- Sharp edge and high hardness: Ensures a precise and efficient cut.

- Eco-friendly machining: It does not produce dust or waste, making it an environmentally friendly option.

- Deburring: The resulting machining is clean and free of burrs, eliminating the need for additional finishing processes.

- Customizable

PCD Inserts

Sharp cutting edge for exceptional surface quality:

PCD inserts offer an extremely sharp cutting edge that ensures superior surface quality and increased productivity. Their exceptional durability extends the tool's lifespan, reducing replacement costs and downtime. Additionally, the optimized chip-breaking groove improves chip control for more efficient machining.

- PCD cutting edge: Unmatched precision and surface quality.

- Higher productivity: Increases machining efficiency.

- Long lifespan: Reduces costs and downtime.

- Optimized chip control: Facilitates chip evacuation and improves safety.

Applications

- High precision machining

- Abrasive materials

- Aluminum alloys

- Composite materials

Carbide end mills

Unequal blade design for superior vibration control:

Our carbide end mills feature an uneven helix design that effectively suppresses vibrations, allowing for a more stable and precise cut. These end mills are suitable for both roughing and finishing machining, offering great versatility.

- Vibration control: The uneven blade design minimizes vibrations for a more stable cut.

- Versatility: Suitable for roughing and finishing operations.

- High-quality coating: Extends the tool's lifespan and enhances performance.

Range of diameters:

- Range of diameter on the guide: ø3 ~ ø20 (0.88" to 3.75")

- Customizable