Services

Tool Wear Analysis: Maximize Your Productivity with GWT

Are you looking to optimize your machining processes and reduce costs? At GWT, we offer you the Tool Wear Analysis service, a comprehensive assessment that will help you identify areas for improvement and increase the efficiency of your production.

What does Tool Wear Analysis consist of?

Our analysis, conducted by GWT experts, evaluates the condition of your cutting tools and compares it to industry standards. This process allows you to gain a clear insight into the potential for savings in tool and machining costs, while also helping you to:

- Reduce machine downtime.

- Minimize rejected parts and rework.

- Optimize the lifespan of your tools.

- Improve the overall equipment efficiency (OEE).

Benefits of Tool Wear Analysis:

Identification of key issues

We detected problems in the machine setup, tool flow management, cutting tool selection, and cutting strategies.

Technical Knowledge Assessment

We analyze the level of knowledge and skills of your operators and engineers.

Quantification of wear patterns

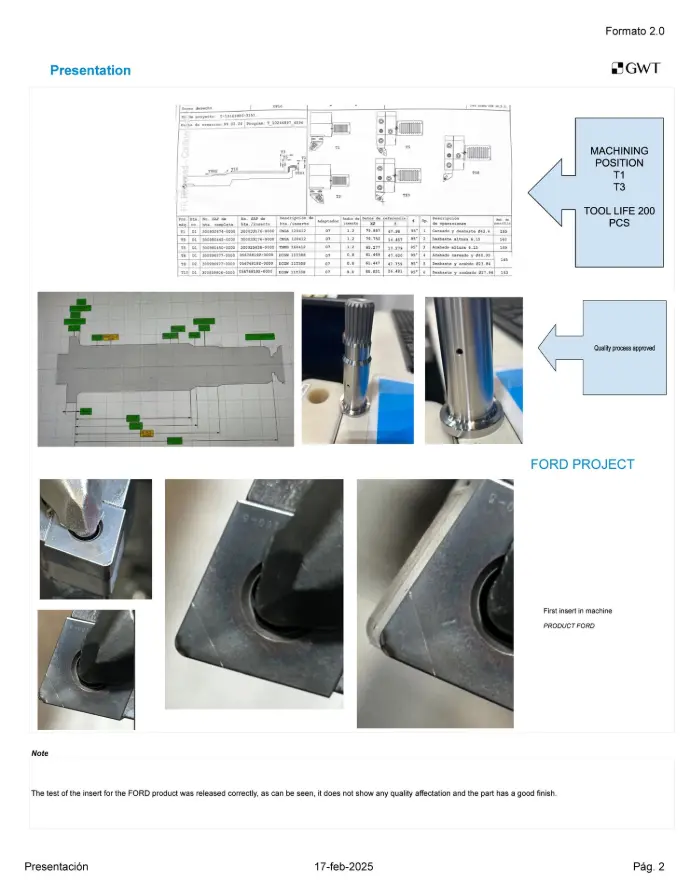

We measure the tool wear and link it to potential machining problems.

Potential savings

We evaluate the potential savings in tool and machining costs.

What do we analyze?

- Cost of machining and tools.

- Stability of the machining process.

- Quality of the finished workpiece.

- Knowledge and skills of machining operators and engineers.

Results:

- A detailed report with the findings of the analysis.

- Specific recommendations to optimize your processes.

- Strategies to improve the selection and use of cutting tools.

- Action plan to increase efficiency and productivity.